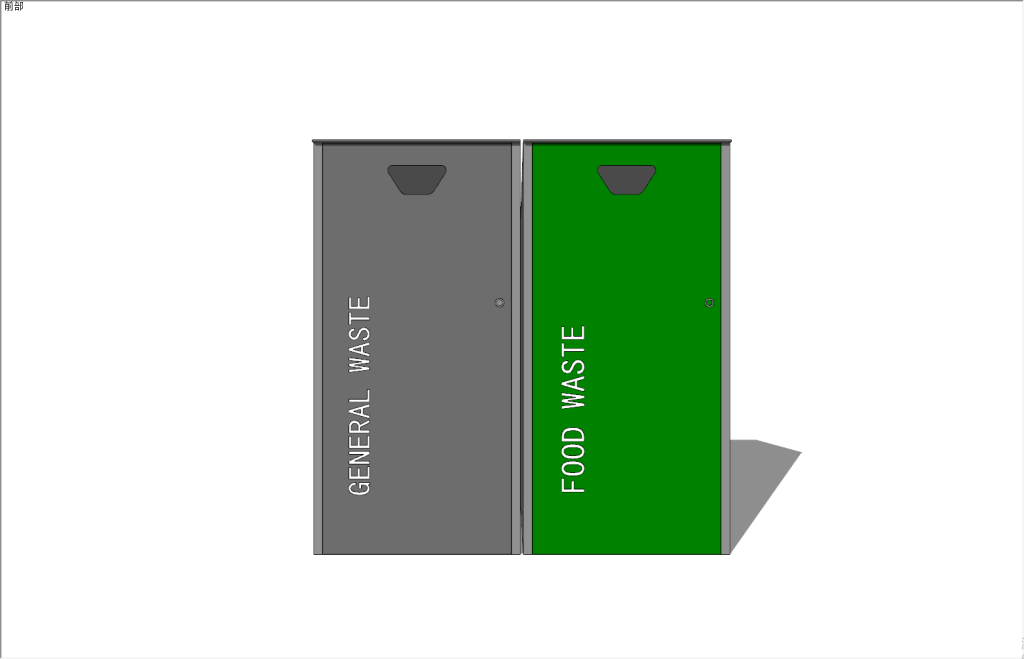

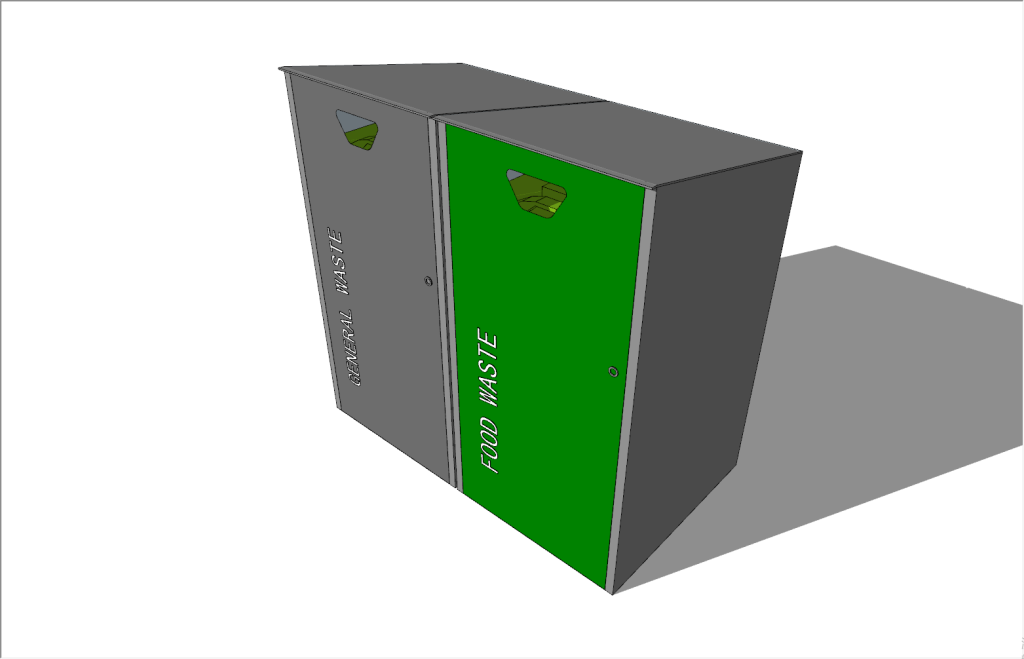

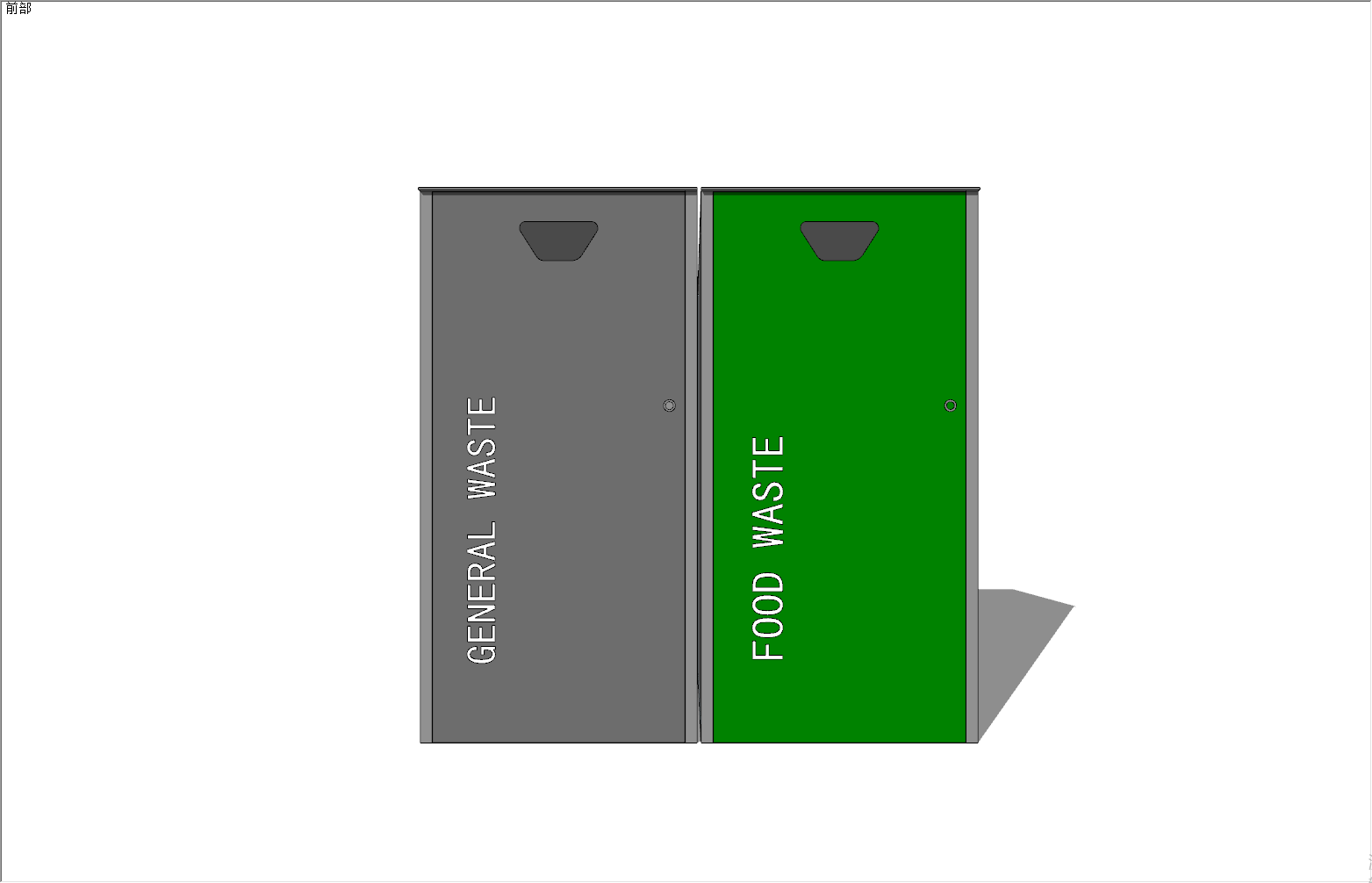

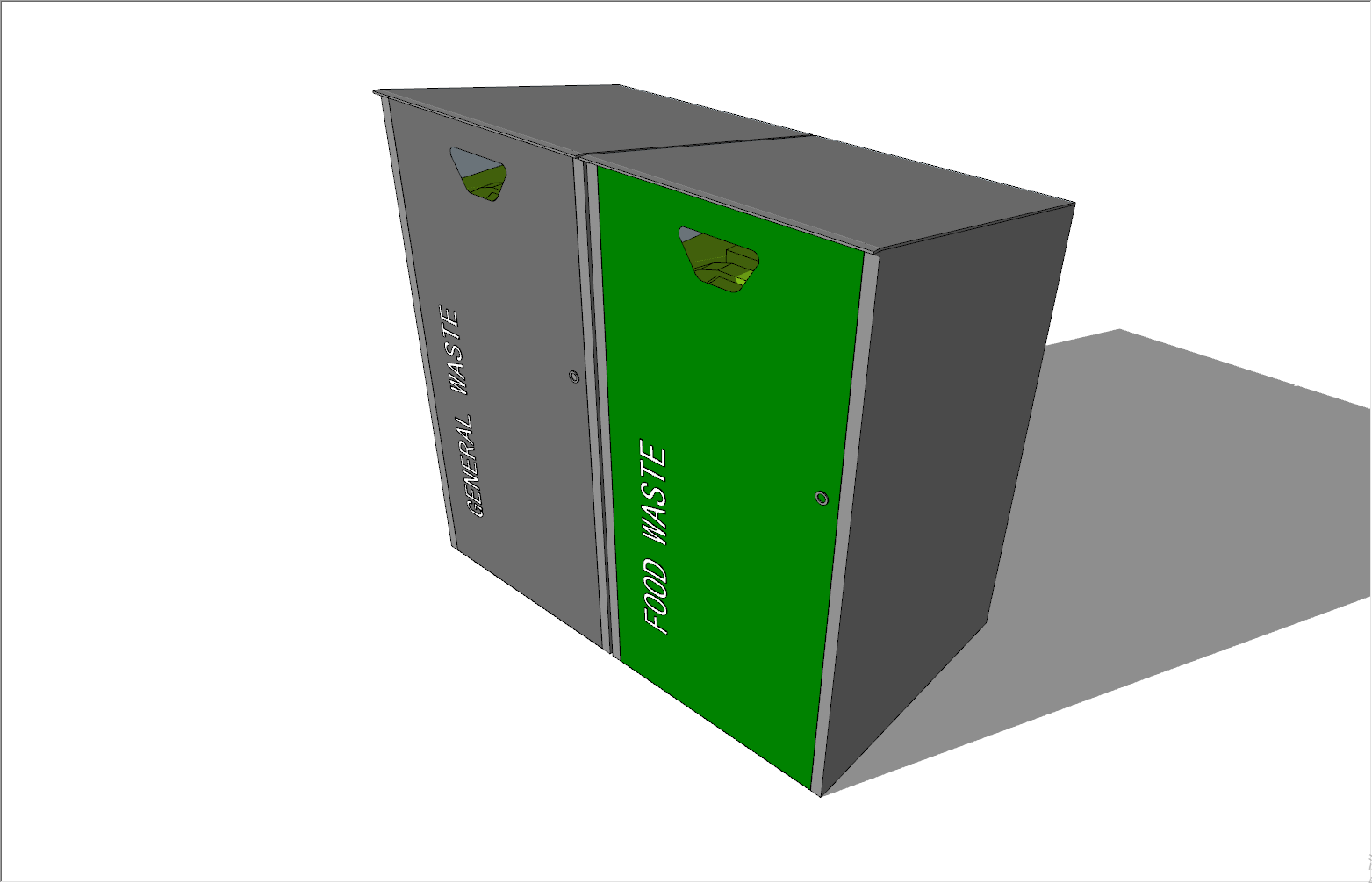

Wheelie Bin Storage Units

Product Type: Metal Wheelie Bin Shell

Material: Galvanised Steel

Applicable Bin Capacity: 50L-240L

Steel Plate Thickness: 0.8mm (regular model; can be customised for scenarios with high load-bearing and impact resistance requirements)

Surface Treatment: Basic: Galvanised layer passivation (enhances rust resistance)

Product Description

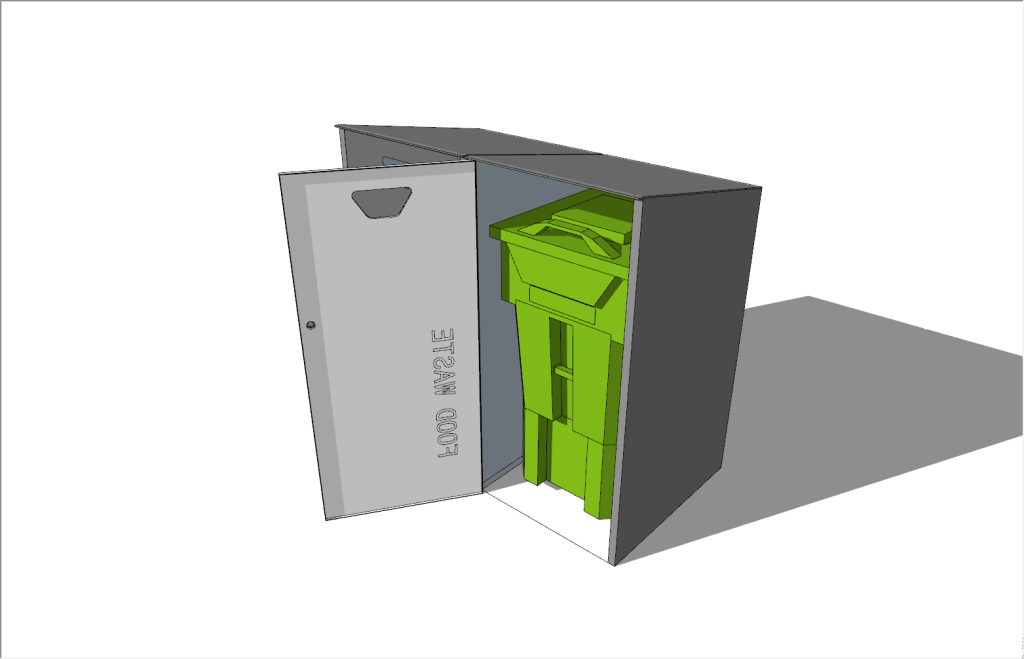

This metal wheelie bin storage unit is an ideal upgrade for outdoor waste management, particularly for housing plastic wheeled bins. It combines a durable metal frame with either a wood texture or metal panels. It is both durable and aesthetically pleasing, integrating perfectly into courtyard, residential, and commercial locations.

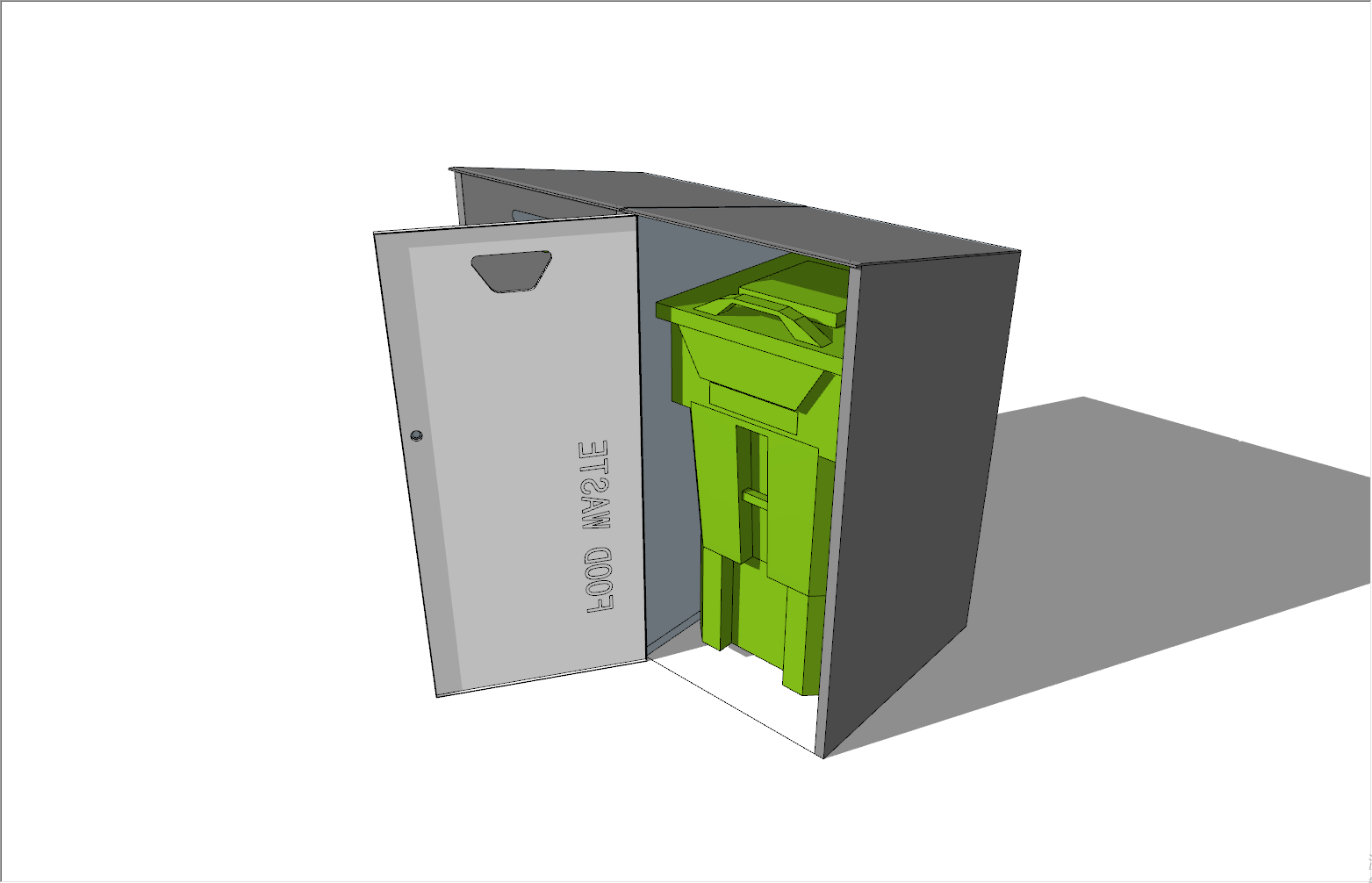

- Storage and Protection: Contains from 1 to 3 wheeled bins. It is flip-top or side-opening for easy access and weather and odour protection, and is animal impervious.

- Quality Details: Long-lasting outdoor performance with lockable doors, antimicrobial ventilation, and metal that won’t rust.

- Style: Select from wood-tone panels or smooth metal finishes to transform waste storage into an appealing element.

This is good for homes or businesses, and combines a practical design and pleasing appearance to make outdoor spaces tidy and organized.

Specifications

| Item | Specification |

| Product Type | Metal Wheelie Bin Shell |

| Material | Galvanized Steel |

| Applicable Bin Capacity | 50L-240L (regular model, compatible with inner buckets of mainstream household/commercial wheelie bins; customized models for larger capacities are available) |

| Processing Procedures | Cutting → Bending → Welding → Grinding → Surface Treatment |

| Surface Treatment | Basic: Galvanised layer passivation (enhances rust resistance); Optional: Color can be customised as required |

| Dimensions | Regular model (for 240L inner bucket): 13507801250mm |

| Weight | Regular model (for 240L inner bucket): 43kg |

| Steel Plate Thickness | Basic: Galvanized layer passivation (enhances rust resistance); Optional: Color can be customised as required |

Features

1. Protection Offered by Advanced Material Science

Galvanised steel offers long-lasting protection. With a protective zinc coating that is permanently bonded to the base metal, there is a continuous defense against air, moisture, and corrosive agents. This greatly minimises the chance of rust developing, especially outdoors. Additional protection is offered by extra-thick steel panels (standard 0.8-1.2mm, customizable for additional protection) and fully welded seams. This dent-resistant structure also maintains its shape upon impact and during everyday activities or accidental hits.

2. Precision in Engineering Every Step of the Way

A tightly controlled multi-step process is used in the manufacture of each wheelie bin storage unit:

- Laser cutting steel ensures dimensional accuracy of 1mm.

- Uniform angles and seamless alignment of edges are achieved through CNC bending.

- Automated welding seamlessly and consistently joins materials without weak spots.

- Protective surfaces are steel ground to smooth edges and eliminate weld marks.

The final result is a finished product that is secure and safe for the user. These steps in the process fully guarantee a safe, flush, and user-friendly finish.

3. Customizable Finishing for Any Environment

In addition to the common rust-resistant galvanised coating, we also provide electrostatic spraying in various colour options (greys, greens, blues, etc.) to align with your branding or environment. The coating’s stickiness and resistance to chips make for a long-lasting coating of minimal upkeep. The product will fit in any residential, commercial, or municipal setting, making it great for durability and design flexibility.

R4. eady-to-Use, No-Fuss Assembly

Every wheelie bin storage unit has been designed to fit most common wheeled bin sizes, and the enclosure keeps the inner container securely in place without any wobbling. Pre-drilled mounting holes fit with standard bin accessories for a quick installation, to avoid custom changes. It’s designed in a way that is the most straightforward for the customers and will ensure the least possible complexity, in turn reducing the overall cost of the project.

Why Choose Us?

- You Get Built-to-Last Durability: As a brand, we begin our process with one of the few nationally certified distributors of galvanised steel that undergoes multiple tests to obtain the optimal composition of rust-proof zinc coating, ensuring durability and structural integrity of the steel throughout time and extensive usage.

- You Get Perfect Fit & Finish: Automated CNC machining provides the highest precision of cutting and bending metals, ensuring the entire unit meets our specifications and is, therefore, accurate to within 1mm of our specifications.

- You Get Industry-Leading Reliability: Consistency is the cornerstone of our quality and reliability. According to the other players in the industry, we have a quality that offers much higher reliability, our triple check process to quality isolate phases, and then reassemble the unit in another phase.

- You Get Scalability & Speed: Over 10 years of proven expertise in our processes, we have the capacity to produce over 500 units daily, and will complete the largest orders in the rapid transactional process we’ve developed over the years.

Customize

This item offers a scale of tailored options. These options are as follows:

- Dimensions: The outer and internal configurations of the enclosure are tailored to the bin that has to be fitted. Capacities of the enclosures are between 50L and 360L, providing a perfect contour fit.

- Coating: Galvanised passivation is standard, but we also offer electrostatic spraying in various colours (Pantone/RAL match is possible, for example, RAL 7035 for grey and RAL 6021 for green). In case of increased corrosion, a dual “galvanised + sprayed” protective coating is available.

- Features & Reinforcement: You can add handle cutout options from the side or front, add lock mounts for protection, increase reinforcement ribs for extra support, or space out logo areas for branding via silk‑screen or embossing.

- Workflow Description: Share your requirements with us → We send you design drawings for your review and a quote → You accept and move forward → Sample production is performed (if applicable) → Sample is reviewed & approved → Bulk order is placed → Production → Quality control → Shipping.

Related Products