Wheelie Bin Storage Metal

| Item | Specification |

| Product Type | Metal Wheelie Bin Shell |

| Material | Galvanized Steel |

| Applicable Bin Capacity | 50L-240L (regular model, compatible with inner buckets of mainstream household/commercial wheelie bins |

| Processing Procedures | Cutting → Bending → Welding → Grinding → Surface Treatment |

| Surface Treatment | 50L-240L (regular model, compatible with inner buckets of mainstream household/commercial wheelie bins; customised models for larger capacities are available) |

| Weight | Regular model (for 240L inner bucket): 43kg |

Product Description

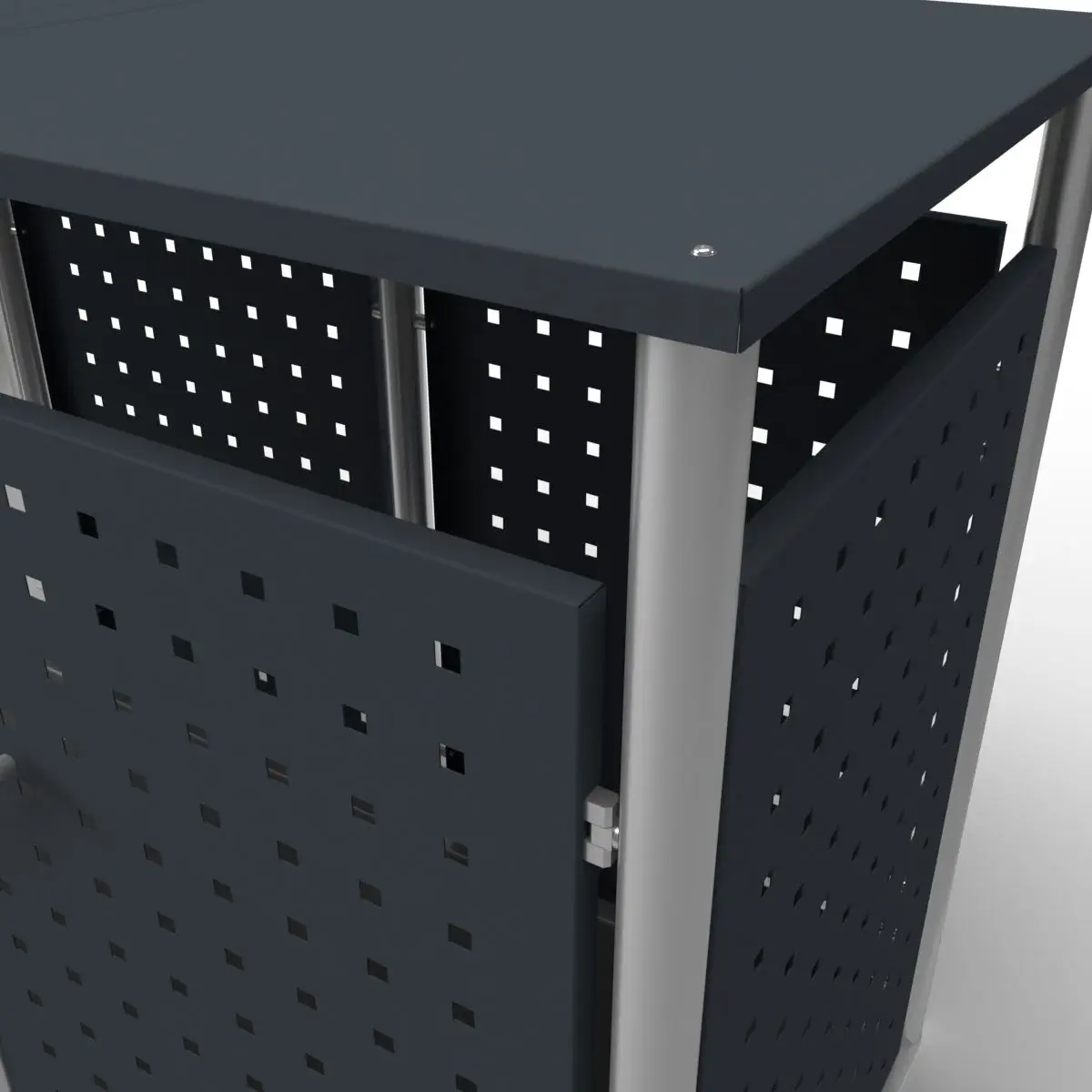

The wheeled bin enclosure manufactured by HD is designed to secure and organize outdoor waste areas while improving their appearance. It comes in wood-grain or full metal finishes, and its sturdy metal structure ensures durability, and at the same time, it is suitable for residential yards, communities, and commercial areas without creating visual disturbance.

The enclosure can hold from one to three bins on wheels, depending on the model, and has a top-opening or side-access system that makes everyday use easier, keeps the rain out, reduces odors, and prevents animals from accessing the bins.

The enclosure’s safety, airflow, and outdoor performance are improved by the ventilated panel spacing, lockable doors, and rust-resistant treatment.

Features

- High-Durability Material with Rust and Impact Resistance: The core is made of galvanized steel, where the zinc layer is tightly bonded to the steel. This can effectively isolate air, moisture, and corrosive substances, greatly reducing the risk of rust in outdoor or humid environments. The 0.8-1.2mm thickened steel plate (thickened customization available), combined with precision welding technology, ensures a stable outer shell structure, which can withstand external impacts such as daily handling and collisions without deformation or cracking.

- Multiple Precision Processes for Reliable Details: From steel cutting (ensuring dimensional accuracy with an error ≤1mm), CNC bending (uniform angles and high edge fit), to seamless welding (smooth welds without missing or virtual welding), and full-surface grinding (removing burrs and weld nodules to avoid scratches during use), each process is strictly controlled to ensure the overall flatness and use safety of the outer shell.

- Flexible Surface Treatment for Multiple Scenarios: The basic galvanized passivation treatment meets regular rust resistance needs; the optional electrostatic spraying process supports customization of various colors, such as gray, green, and blue (which can match the customer’s brand color or scene tone). Moreover, the coating has strong adhesion and is not easy to fall off, enabling it to maintain a clean appearance for a long time and adapt to the aesthetic needs of different scenarios such as residential areas, commercial places, and municipal areas.

- Precise Size Compatibility for Easy Installation: The size of the outer shell is designed according to the specifications of the inner bucket of mainstream wheelie bins. After the inner bucket is placed, the fit is good without shaking. Reserved wheel installation holes have strong compatibility with regular wheelie bin accessories, allowing customers to quickly assemble without additional modifications, reducing installation costs.

Why Choose Us?

- Professional Material Control for Stable Quality: We carefully select galvanized steel raw materials that meet national standards. Each batch of steel undergoes composition testing and zinc layer thickness testing to ensure that the raw materials meet the standards for rust resistance and load-bearing performance. During the production process, 3 quality inspection links are set up (in-process quality inspection, finished product dimensional inspection, and surface performance inspection) to eliminate substandard products from leaving the factory. The quality stability is far higher than the industry average level.

- Mature Process System for High Production Efficiency: With more than 10 years of experience in galvanized steel product processing, we use CNC cutting and CNC bending equipment, which ensures high processing accuracy (dimensional error ≤1mm). The production process is standardized, and the daily output of regular models can reach more than 500 pieces. This enables us to quickly respond to customers’ bulk order needs and shorten the delivery cycle.

- Strong Customization Capability for Personalized Needs: We support the customization of outer shells according to the customers’ provided wheelie bin inner bucket size, load-bearing requirements, and color preferences. We can adjust the steel plate thickness (1.0-1.5mm), modify the dimensional parameters, customize special color coatings, and even reserve positions on the outer shell surface for logo pasting/silk-screen printing according to requirements, meeting the customers’ personalized supporting needs.

- Comprehensive After-Sales Guarantee for Worry-Free Cooperation: If customers find quality problems such as dimensional deviation and surface damage after receiving the products, we promise to respond within 48 hours and provide free replacement or return services. For customers with bulk purchases, we can provide a 1-year quality guarantee (for rust and cracking caused by non-human damage under normal use, free repair or replacement is available), reducing the customers’ use risks.

Customize

Dimensions and Fit

The size of the enclosure and its internal configuration can be modified according to the customer’s specifications for wheeled bins or the space available for installation, thus providing a stable and correctly aligned placement. The following bin sizes can be catered for: 50L, 80L, 120L, 240L, and even 360L, which guarantees that the product will be compatible with a large number of standard containers.

Surface Finish Options

The customer has the option to choose from a variety of finishes, standard hot dip galvanizing being one of them, and the other being powder coating in custom colors. The color matching can be done very accurately to the Pantone or RAL reference colors, like gray, green, or blue. The customers who are situated in harsh environments can have a combination of galvanizing and powder coating as a dual treatment in order to get increased corrosion resistance.

Structural and Functional Adjustments

The design may be changed according to the customer’s will, with pre-cut handle openings, theft-proof lock holes, the addition of reinforcing ribs for higher tensile strength, and areas reserved for customer logos through screen printing or embossing, where the position and size of the logo will be determined by the customer.

Customization Workflow

The workflow begins with the customer providing the required specifications, and then the design drawings and pricing are done. When the drawing is approved and the sample is confirmed (if necessary), the bulk order is placed, and the production is done under quality control, after which the product is delivered to the customer once the inspection is approved.

Related products