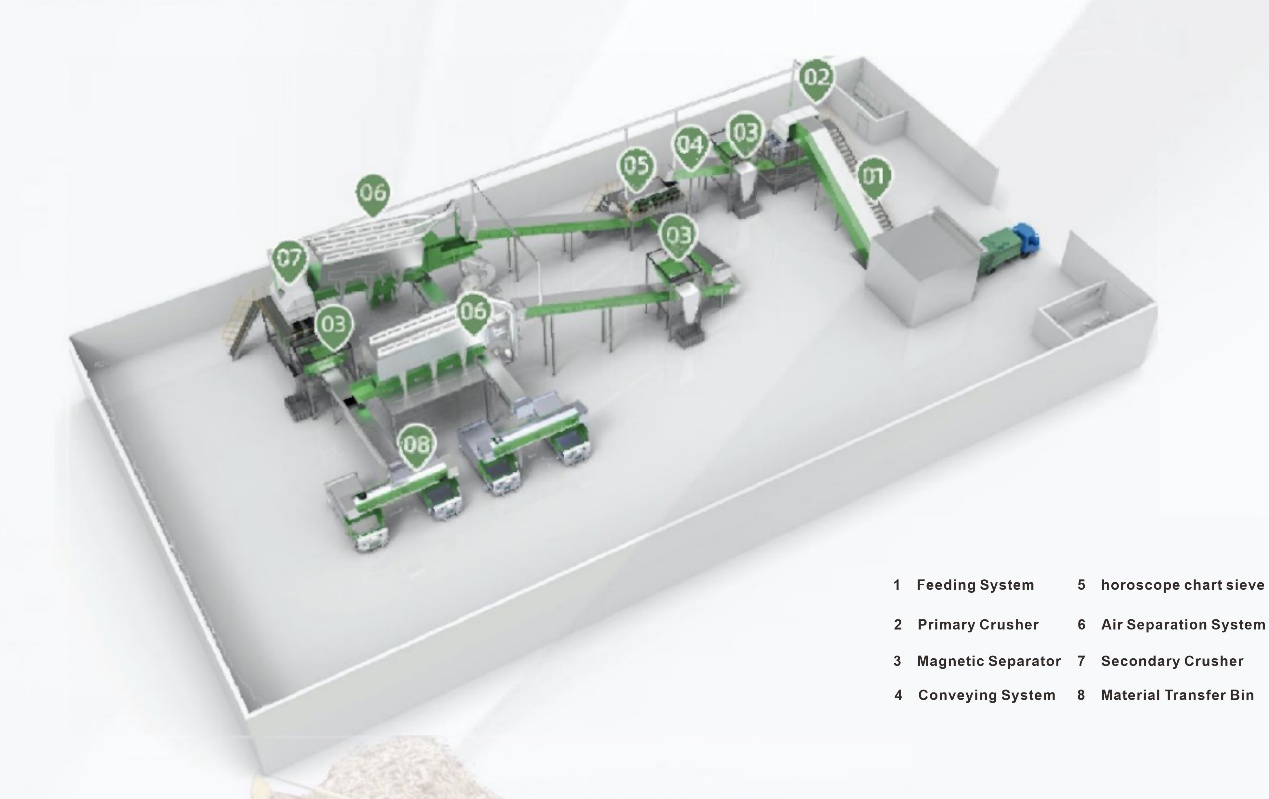

Residential and Commercial Waste Sorting System

With rapid urban expansion and rising living standards, the annual volume of municipal solid waste continues to grow. To solve the problem, HD developed residential and commercial waste sorting systems.

Features of the Residential and Commercial Waste Sorting System

Our waste sorting system provides a fully enclosed, automated process designed for safe unloading, efficient material separation, and high-quality RDF production.

1. Fully automated, enclosed unloading

We begin with the disposal of municipal solid waste in a sealed unloading station. Roller shutter doors open automatically using photoelectric sensors, radar, or cameras. Unloading triggers the automatic system for control of sterilisation, disinfection, and negative-pressure deodorisation. This provides a system that is clean, odourless, and sanitary.

2. Initial separation and crushing

- This waste is forced by a plate feeder into the primary crusher. This is a system that remains closed for the entire process, primarily for the control of system leakage. Here, the bags are broken, and other materials are reduced to less than 250 mm. Crushed materials then continue through the conveyor to the system for magnetic separation to remove all ferrous metals. Then enter the star disc screen, then the drum screen. The purpose of the drum screen is a two-way separation of the waste into:

- oversized (+80 mm)

- undersize (-80 mm)

3. Handling Oversized Material

- Oversized material processes in the air separator that separates the heavy from the light components.

- Discharge heavy materials (stones, glass, concrete) to their respective landfill locations.

- Light materials (paper, plastic, other combustibles) are directed to the secondary crusher. After size reduction, the material is processed to become sorted and magnetically separated to RDF.

4. Handling Undersized Material

For magnetic separation to remove the last remaining ferrous metals, undersized material is processed. To the landfill, the remaining heavy inert fraction (stones, glass, concrete) is transported, and thus the classification stage is completed.

①Industrial and Commercial Waste Treatment System

The Closed Automated System’s Design Allows Efficient Handling of Business and Industrial Waste and Guarantees Superior Rates of Material Recovery and Consistent Output of RDF.

- Primary Reduction and Screening

Commercial and industrial waste is discharged directly into the coarse-crusher hopper from specialised transport vehicles. During this process, bags are opened, and the material size is decreased to under 250 mm. Then the crushed substance is transported to the star disc screen, where the waste is classified into oversized and undersized. A magnetic separator is used to extract ferrous metals in-line during screening.

- Air Separation of Oversize & Undersize Fractions

- The air-separator is being used for density-driven separation of both fractions:

- Heavy constituents, including stones, glass, and concrete, go to specific landfill sites.

- Light combustibles like paper and plastics proceed to the secondary crushing stage.

- Secondary Crushing & RDF Production

Light materials are processed in the secondary crusher for additional refinement. Then, at the closing magnetic separation stage, retrievable ferrous metals are removed. The resulting material is then converted to high-grade RDF (Refuse-Derived Fuel) for use in various energy recovery processes.

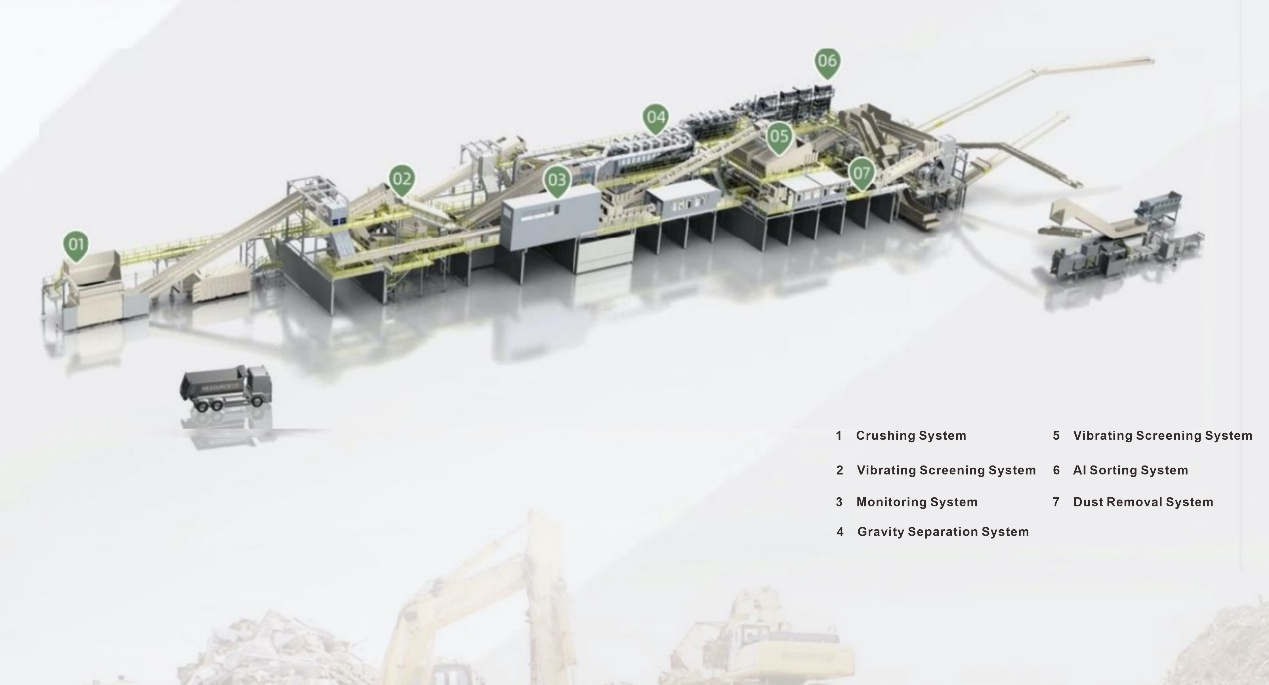

②Industrial and Commercial Waste Management System

In order to improve our further resource recovery, module processing with composite screens, vibrating screens, and AI-enhanced robotic sorting, our system incorporates an optimal processing configuration. This new configuration allows for the exact split of commercial and industrial (C&I) waste streams.

- Accurate Separation of Materials

The system recovers and efficiently separates from the waste streams wood, paper, fibres, metals, concrete, bricks, and more. All of the recovered fractions undergo direct downstream transport for recycling or reuse.

- Enhanced Recovery from C&I Waste

C&I waste also includes light mixed materials comprising wood, plastics, cardboard, paper, and minor portions of concrete, rubble, soil, etc. By way of multiple stage screening and sorting, the combustible portion has ferrous and non-ferrous metals, inert materials and non-recyclables removed.

- High-Value Output Streams

- Combustible materials are refined into PEF (Processed Engineered Fuel), providing an energy-efficient alternative to fossil fuels.

- Inert materials like bricks and concrete are recycled and provided to civil construction as alternatives to conventional quarry materials.