Outdoor Wheelie Bin Storage

Material: Galvanised Steel

Surface Treatment: Basic: Galvanised layer passivation (enhances rust resistance); Optional: Colour can be customised as required

Dimensions: Regular model (for 240L inner bucket): 13507801250mm

Weight: Regular model (for 240L inner bucket): 43kg

Applicable Bin Capacity: 50L-240L (regular model, compatible with inner buckets of mainstream household/commercial wheelie bins; customised models for larger capacities are available)

Product Description

A Tidy, Aesthetic, and Protective Outdoor Waste Management Solution

- Purpose-built for wheeled bins: The metal wheelie bin storage unit neatly houses plastic wheeled bins, enhancing both quality and aesthetics in outdoor waste storage. Its robust metal frame, combined with wood-like or full-metal panels, presents strength while perfectly blending into courtyards, residential areas, and commercial spaces.

- Efficient storage & reliable protection: Capable of accommodating 1–3 wheeled bins (depending on model), the enclosure features a top flip lid or side-opening structure for easy disposal and collection. It protects bins from wind and rain, contains odours, and prevents animals from accessing waste, keeping the surroundings clean and orderly.

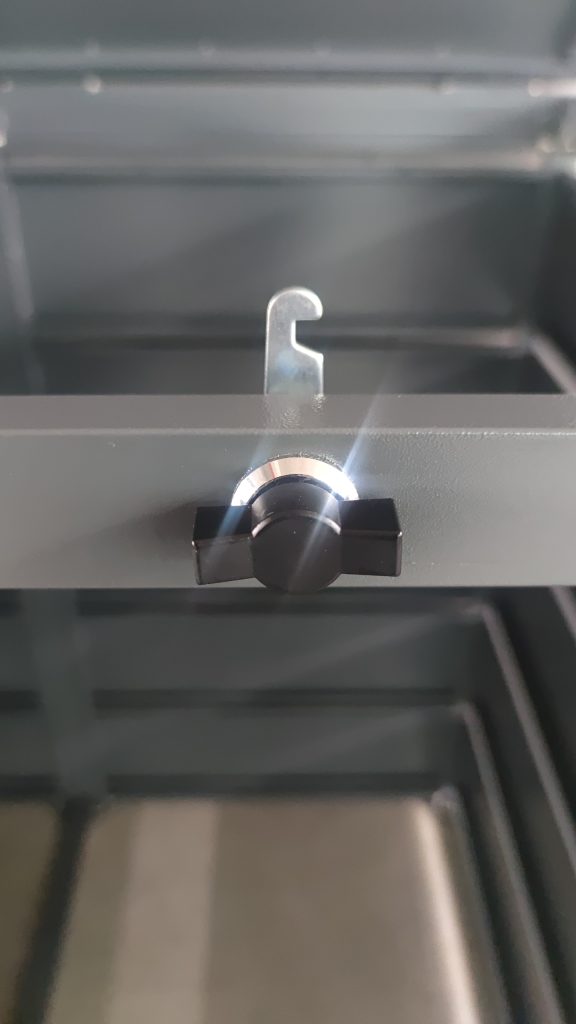

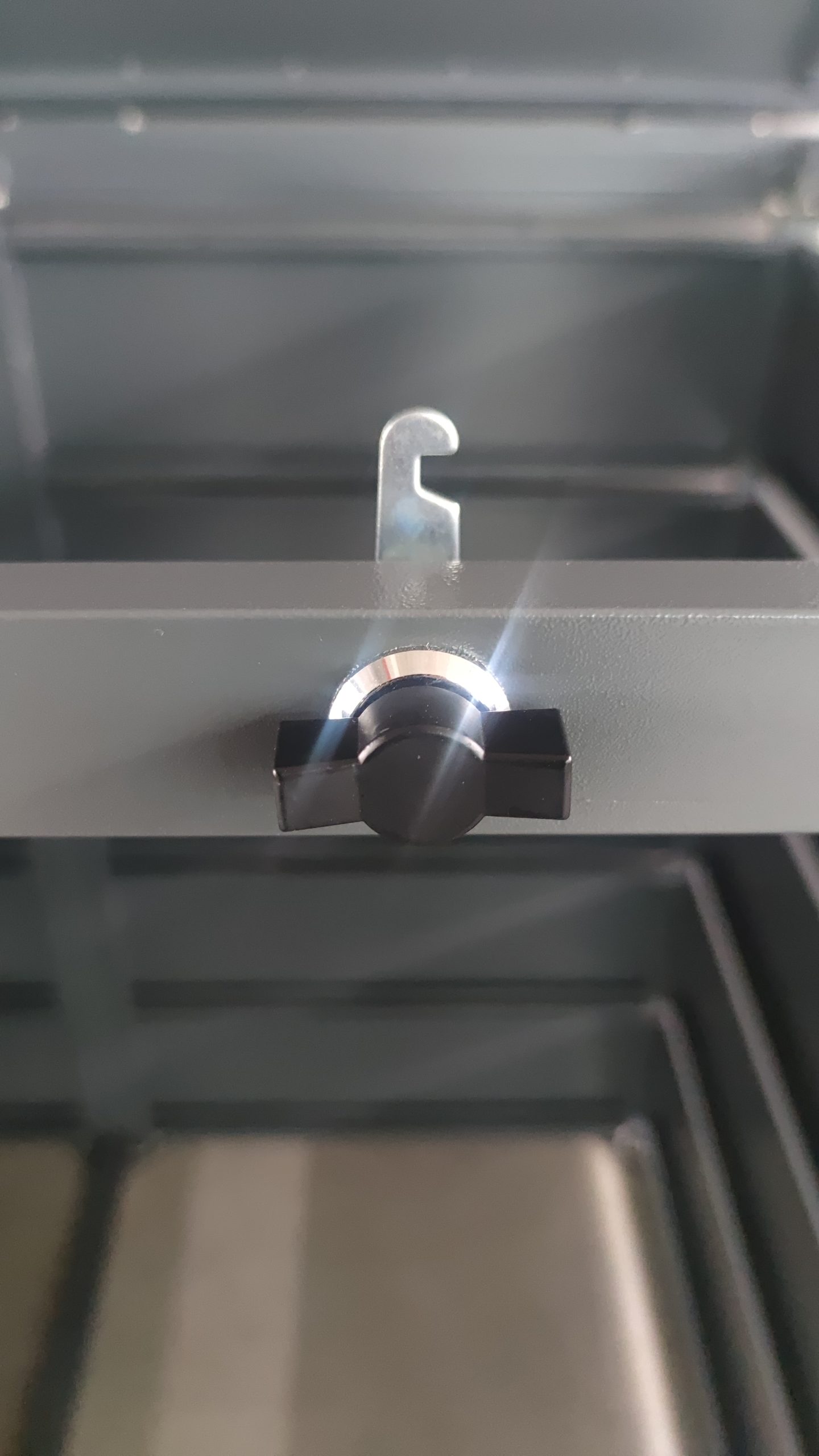

- Quality in every detail: Each unit has a lock system and carefully placed panels to facilitate both ventilation and visual appeal. The metals are anti-rust treated to ensure long-term stability and dependable outdoor performance.

- Several styles for different environments: Choose from warm, wood-texture designs to sleek industrial metal finishes to suit different settings. These enclosures elevate waste storage from eyesore to refined element of the landscape.

- Ideal for both homes and businesses: This outdoor wheelie bin storage gives a practical, attractive, and durable way to manage the outdoors, whether to enhance a neat home courtyard or give that professional image to a commercial area.

Specifications

| Item | Specification |

| Product Type | Metal Wheelie Bin Shell |

| Material | Galvanized Steel |

| Applicable Bin Capacity | 0.8mm (regular model; 1.5mm thickened model can be customised for scenarios with high load-bearing and impact resistance requirements) |

| Processing Procedures | Cutting → Bending → Welding → Grinding → Surface Treatment |

| Surface Treatment | 50L-240L (regular model, compatible with inner buckets of mainstream household/commercial wheelie bins; customised models for larger capacities are available) |

| Dimensions | Regular model (for 240L inner bucket): 13507801250mm |

| Weight | Regular model (for 240L inner bucket): 43kg |

| Steel Plate Thickness | 0.8mm (regular model; 1.5mm thickened model can be customized for scenarios with high load-bearing and impact resistance requirements) |

Why Choose Us?

1. Certified Raw Materials for Lasting Strength

HD only work with establishments accredited at the national level, vouching for the galvanised steel that we procure. The batch samples are drawn from the lab for rust resistance testing to verify that the structure remains intact, and that they are the best at their zinc coating, rust, and at the chemical composition to keep the zinc caucuses safe.

2. Precision Engineering with Advanced CNC Technology

Automated CNC cutting and bending machinery was employed to attain the edge. That gives them the full right to brag about how much more every piece is intact and the same, finished.

3. Rigorous Triple-Check Quality Assurance

Quality is inspected at three critical stages: during production, after completion for dimensions, and for final surface performance. This multi-layered system eliminates defects, delivering a reliability rate far above industry standards.

4. To Increase Speed and Guarantee Volume

With over a decade of specialised experience and standardised processes, we achieve very high outputs of over 500 standard units every day. As a result, we can fulfil very large orders and guarantee quick turnaround times.

Customize

This product supports comprehensive customisation services, with the specific customization scope as follows:

- Size Customization: According to the wheelie bin inner bucket size (height, width, depth) or actual installation space requirements provided by the customer, adjust the overall size and internal structure of the outer shell to ensure a perfect fit with the inner bucket/installation scenario (the minimum customized size can support a 50L inner bucket, and the maximum can support a 360L inner bucket).

- Surface Treatment Customization: In addition to the basic galvanized passivation, electrostatic spraying color customization is supported (Pantone color card number matching is provided, common colors include RAL 7035 gray, RAL 6021 green, RAL 5010 blue, etc.); “galvanizing + spraying” double-layer protection can also be customized (suitable for high-corrosion environments such as coastal areas and industrial zones).

- Structure and Function Customization: According to requirements, handle holes and lock installation holes (for anti-theft) can be reserved on the side/front of the outer shell; reinforcing rib design can be added (to enhance the load-bearing capacity of the outer shell); positions for logo silk-screen printing/embossing can also be reserved on the outer shell surface (the position and size can be customized).

- Customization Process: The customer provides customization requirements (size, material, surface treatment, function, etc.) → we issue the design drawing and quotation → the customer confirms the drawing and pays the sample fee (if needed) → make and send the sample → the customer confirms the sample → sign the bulk order → mass production → deliver after passing quality inspection.