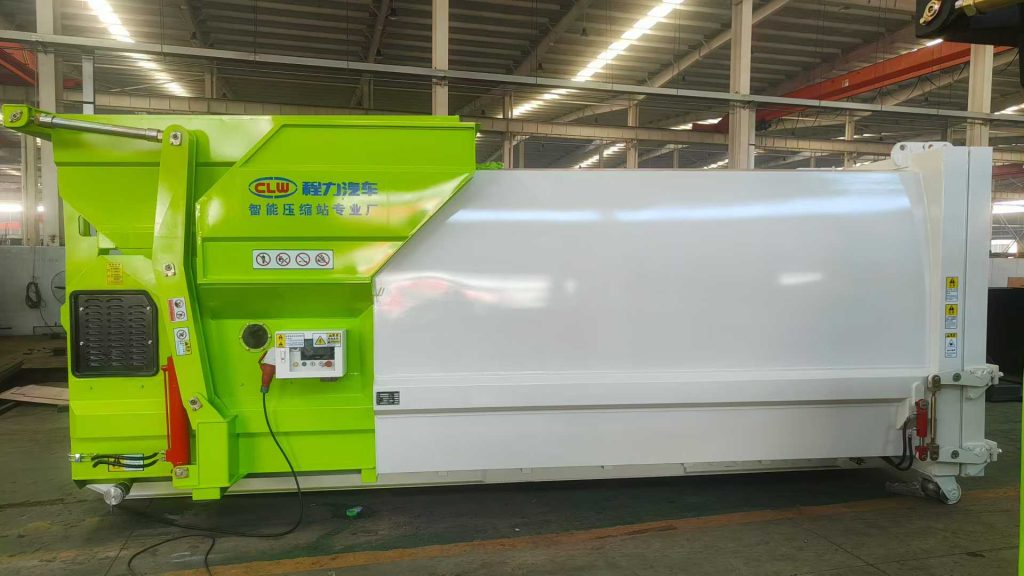

Mobile Waste Compactor

The smart mobile waste compactor is an intelligent mobile sanitation device integrating an intelligent control system with waste compression functions. It can accomplish the whole process of operations, such as “collection-compression-temporary storage,” around waste generation points. It has great value in that it can effectively improve the efficiency of garbage processing and minimize secondary pollution at its source, making operations of urban sanitation flexible and effective.

HD offers OEM&ODM service for mobile waste compactor, please feel free to contact us!

Core Functions

1. Intelligent Management & Control: IoT-driven Remote Operation and Maintenance

Based on the IoT technology, HD mobile garbage compactor can collect three kinds of fundamental data accurately in real-time for the station, including waste filling level, compression pressure, and equipment operation status. It supports the issuing of remote scheduling instructions and early warning of equipment failure, which can completely replace frequent manual inspections in the traditional mode, reducing the labor cost and management difficulty in operation and maintenance.

2. Efficient Compression: Cost Optimization by Significant Volume Reduction

By applying the technological process of hydraulic or mechanical compression, the volume of wastes can be reduced to 1/3-1/5 of the original volume, thus reducing the frequency of waste transportation directly. Given the daily processing capability of the station, ranging from 5 to 20 tons per unit, it greatly reduces the fuel consumption of sanitation vehicles and transportation costs while raising the overall operational efficiency.

3. Flexible Mobility: Adaptation to Scenario without Infrastructure Dependence

With a traction device or self-propelled function, equipment can dynamically adjust the deployment location in accordance with the amount of waste generated in different areas and adapt to diverse scenarios, such as residential communities, business districts, and construction sites. It does not require the construction of fixed infrastructure, solving the pain point that traditional waste stations are difficult to build in old communities and temporary areas.

4. Environmental Sealing: Full-process Pollution Prevention and Control

It adopts a dual-sealing design for leakage prevention and odor prevention. The sewage that will be generated during the compression process can, through a channel exclusively prepared for this purpose, be collected centrally and treated, which can prevent waste leachate from seeping into and polluting soil and underground water at the source. Meanwhile, it reduces odor diffusion and minimizes impacts on the surrounding environment.

Key Advantages

| Advantage Dimension | Specific Value |

| Cost Reduction & Efficiency Improvement | Reduced transportation trips → lower fuel consumption; replacement of manual inspections → reduced labor costs; high processing capacity per station → improved overall operational efficiency |

| Environmental Improvement | On-site nearby treatment → shortened time of waste being piled up in the open air; sealed design → reduced odor diffusion; pollution prevention and control → reduced risk of mosquito and fly breeding, optimizing the sanitation of the surrounding environment |

| Flexible Adaptation | No need for fixed infrastructure; can be quickly deployed in scenarios where traditional waste stations are difficult to cover, such as old communities and temporary construction areas |